Power tools have become indispensable in both professional and DIY environments, offering unmatched efficiency and precision. To fully harness the capabilities of these tools, it's essential to understand their classifications. In this article, we explore the three primary classifications of power tools, providing comprehensive insights into each category, its subtypes, and their specific applications.

Power tools can be classified based on the type of power source they utilize. This classification is crucial as it affects the tool's mobility, power output, and suitability for specific tasks.

Electric Power Tools

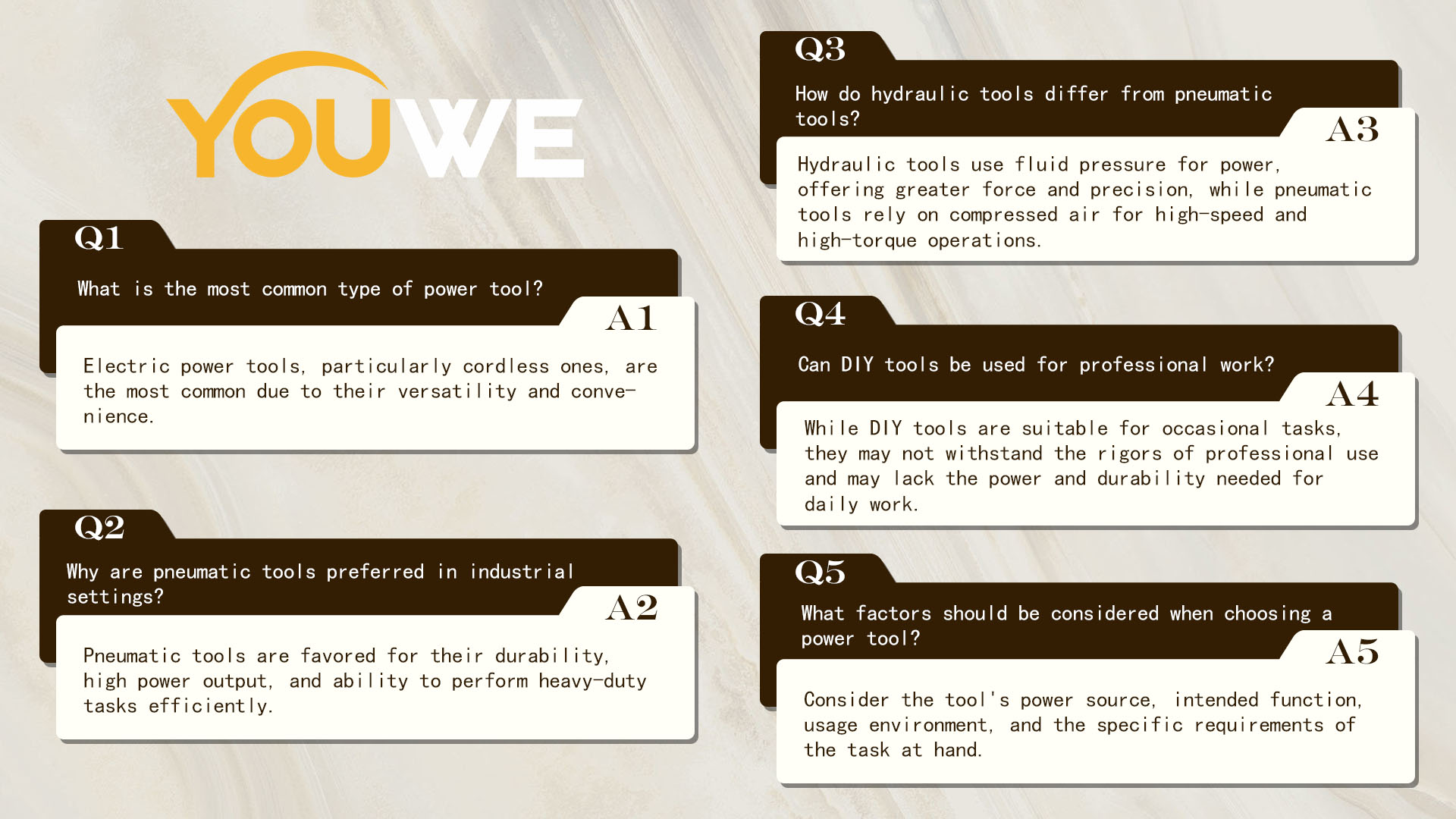

Electric power tools are the most commonly used due to their versatility and ease of use. They are powered by electricity, either through a direct connection to an electrical outlet (corded) or via rechargeable batteries (cordless).

- Corded Electric Tools: These tools are connected to an electrical outlet, providing a continuous power supply. They are ideal for tasks that require sustained power, such as drilling through hard materials or cutting large sections of wood.

Corded Power Tools:

Corded drills

Corded circular saws

Corded jigsaws

Corded sanders

Corded routers

Corded Angle grinders

- Cordless Electric Tools: Powered by rechargeable batteries, these tools offer greater mobility. They are suitable for tasks in areas without easy access to power outlets. However, their usage time is limited by battery life, making them less ideal for prolonged tasks.

Cordless Power Tools:

Cordless drills and scrwedrivers

Cordless circular saws

Cordless miter saw

Cordless vacuum cleaner

Cordless leaf blower vacuum

Cordless air compressor for tires

Pneumatic Power Tools

Pneumatic tools are powered by compressed air, making them highly efficient and powerful. They are often used in industrial settings where consistent high power is required.

- Applications: Commonly used in automotive repair, construction, and manufacturing, pneumatic tools are ideal for tasks such as tightening bolts, cutting metal, and spraying paint.

- Advantages: Pneumatic tools are known for their durability and ability to deliver high torque, making them suitable for heavy-duty applications.

Hydraulic Power Tools

Hydraulic tools use fluid pressure to generate power. These tools are often used in specialized industrial and construction applications where high force is required.

- Applications: Hydraulic tools are commonly used in tasks such as lifting heavy objects, crimping, and cutting metal cables.

- Advantages: They offer immense power and precision, making them ideal for tasks that require both strength and control.

Function-Based Classification

This classification is based on the primary function or purpose of the tool. Understanding these categories helps in selecting the right tool for specific tasks, enhancing efficiency and safety.

Cutting Tools

Cutting tools are designed to cut through various materials, including wood, metal, plastic, and more. They are essential in construction, woodworking, and metalworking.

- Types: Saws (circular, jigsaw, reciprocating), shears, and cutting torches are common examples of cutting tools.

- Applications: Used in tasks such as trimming, shaping, and sectioning materials to the desired size and shape.

Drilling and Boring Tools

These tools are designed to create holes or enlarge existing ones in materials like wood, metal, and concrete.

- Types: Drills (hammer, rotary, impact), augers, and boring machines fall under this category.

- Applications: Essential in construction, carpentry, and metal fabrication for tasks such as creating holes for fasteners, wiring, and plumbing.

Fastening Tools

Fastening tools are used to secure materials together, ensuring stability and strength in various constructions.

- Types: Screwdrivers (electric, impact), nail guns, and staplers are examples of fastening tools.

- Applications: These tools are crucial in assembling furniture, constructing frameworks, and installing fixtures.

Usage-Based Classification

This classification is based on the environment and frequency of tool usage. It helps in understanding which tools are best suited for specific work conditions.

Industrial-Grade Tools

Industrial-grade tools are designed for heavy-duty use in manufacturing, construction, and other industrial settings. They are built to withstand continuous use and harsh conditions.

- Characteristics: High durability, enhanced power, and resistance to wear and tear are key features of industrial-grade tools.

- Applications: Commonly used in factories, construction sites, and large-scale production environments.

Professional-Grade Tools

Professional-grade tools are designed for tradespeople and professionals who require reliable performance for daily tasks. These tools offer a balance between power, durability, and ease of use.

- Characteristics: These tools are robust enough for daily professional use but are generally lighter and more ergonomic than industrial-grade tools.

- Applications: Used by electricians, plumbers, carpenters, and other skilled tradespeople for tasks such as installation, repair, and maintenance.

DIY and Home Use Tools

These tools are designed for occasional use by hobbyists and DIY enthusiasts. They are typically more affordable and user-friendly than professional or industrial-grade tools.

- Characteristics: DIY tools are lightweight, easy to handle, and come with features that make them suitable for home projects.

- Applications: Ideal for home improvement tasks, furniture assembly, and small repairs.

Understanding the classifications of power tools is essential for selecting the right tool for the job, ensuring both efficiency and safety. Whether you're a professional tradesperson or a DIY enthusiast, knowing the differences between electric, pneumatic, and hydraulic tools, as well as their specific functions and usage contexts, will help you make informed decisions.

Contact: Candy

Phone: 18869941430

E-mail: Inquiry@cnyouwe.com

Whatsapp:+86-18869941430

Add: Building 6 Mingyang Park,1389 Jinyuan Road,Chisong Town,Jinhua city,zhejiang